In addition synventive also supplies a complete line of active gate control systems a family of patented technologies to precisely control the flow of melt within the mold.

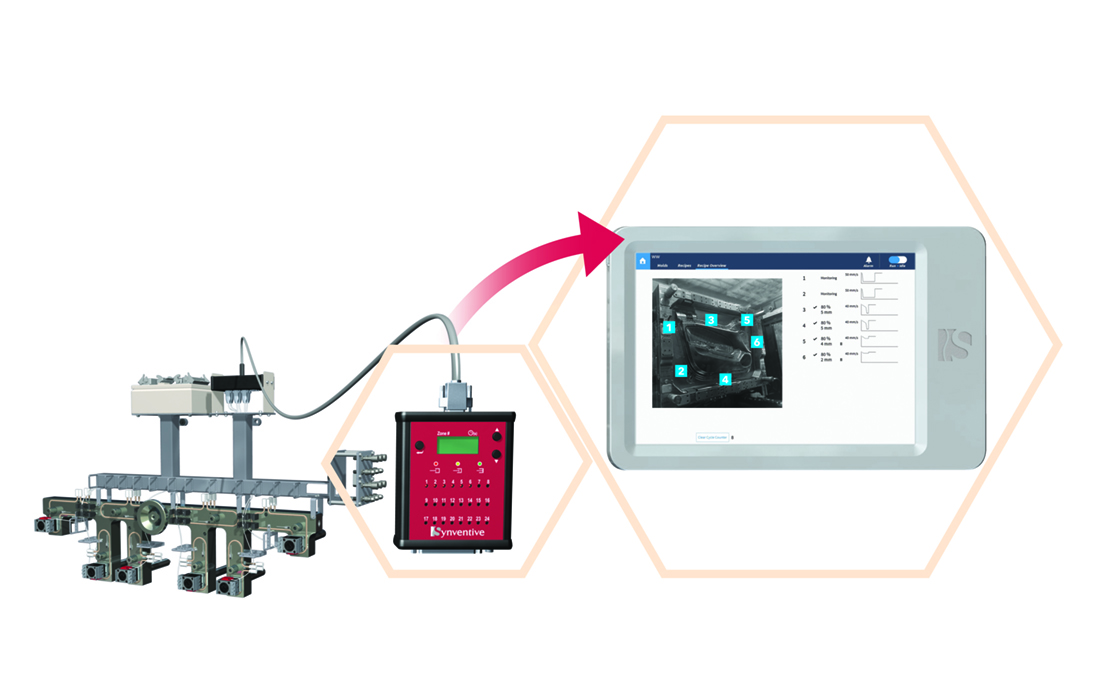

Synventive valve gate controller.

Ttc series manufacturers of large complex or difficult to fill parts often turn to sequential valve gate control svgc to solve molding issues.

All svgc applications have hot runner manifold systems with either pneumatic or hydraulic valve gates.

Synventive is the leading hot runner supplier to the global automotive industry.

Sequential valve gate controller.

Hot sprue bushings and hot runner temperature controllers for the injection molding industry synventive molding solutions continually excels at serving the most demanding needs of a wide array of industries.

Sequential valve gate svg.

Every gate receives the precise injection and pack pressure that is predefined for their position giving you the same level of control as having separate injection units at each hot runner nozzle.

Dynamic feed provides individual melt pressure control in each gating area.

Whether you want 2 zones or 640 zones of temperature control looking to control up to 32 valves gates or maybe control both temperature and valve gates then the lec the g24 and ttc family of hot runner controllers are just what you are looking for.

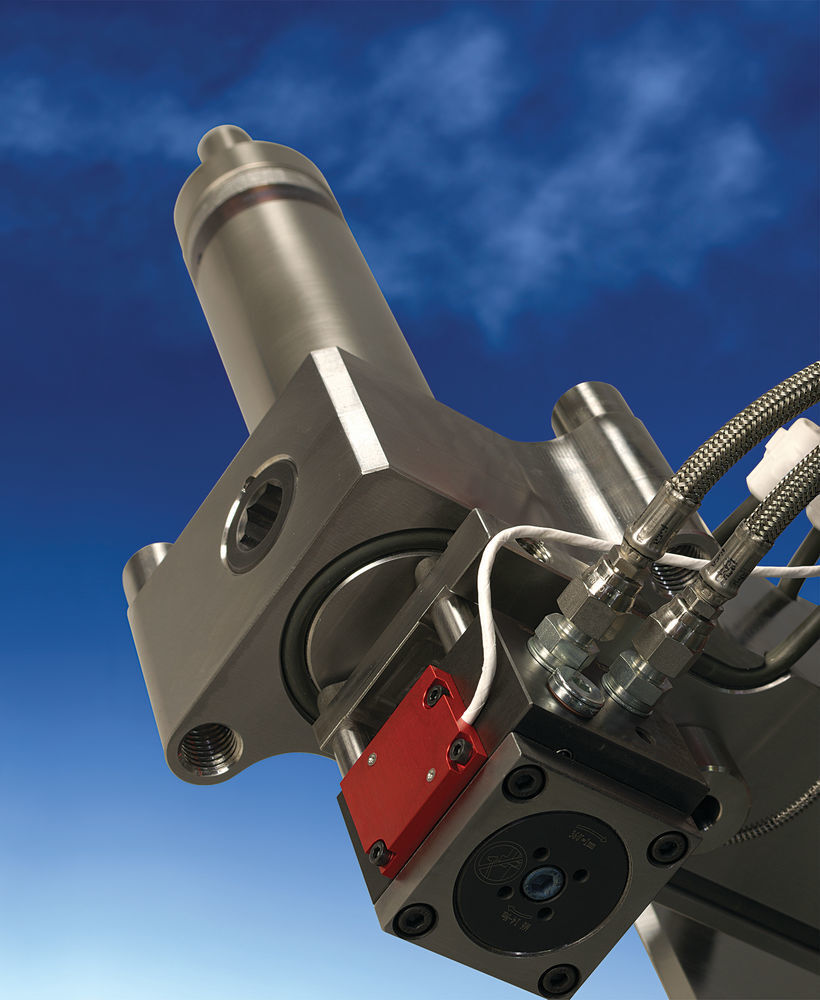

Hydraulic and electric valve gates and plug and play manifolds.

As the leading supplier and innovator we continually strive to perfect our hot runner solutions providing the most efficient way to achieve superior molded parts.

Synventive proudly offers the top line of hot runner temperature and valve gate controllers from our sister company gammaflux.

Egate electric valve gate hot runner systems feature patented technology to precisely control each valve pin s position acceleration velocity and stroke allowing processors the unique ability to control the flow rate out of each nozzle gate at any time during the fill process.

Valve technology to control the melt flow has long been established in the form of valve gate nozzles.

Egate electric valve gate hot runner systems feature patented technology to precisely control each valve pin s position acceleration velocity and stroke allowing processors the unique ability to control the flow rate out of each nozzle gate at any time during the fill process.

Dynamic feed melt pressure control.

Sequential valve gate svg.

Our wide range of products and experience backed by our.

This technology is now available on all synventive hot runner nozzle sizes.